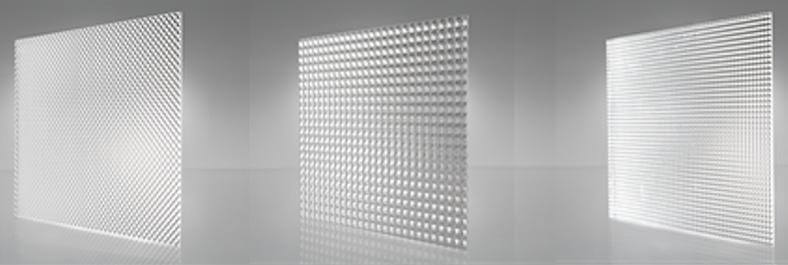

As a uniform light, the diffuser has functions of shielding light source, LGP outlets, and defects. Its main materials are PMMA, PS, PC, PP. In the following, we will show you their characteristics and differences.

PMMA diffuser plate-commonly known as an acrylic diffusion plate

1.PMMA diffuser plate has excellent weather resistance. General indoor use, 3 or 5 years will not change to yellow and brittle(in the ultraviolet aging accelerated test, not easily yellowing phenomenon), at the same time, it has a good high-temperature performance.

2. PMMA diffusion Plate has good printability and spraying. Using printing and spraying technology, you can give acrylic products an ideal surface decoration effect.

3. Ignition resistance: not spontaneous combustion and not self-quenching.

4. High dimensional Stability: water absorption warpage is small, the size of good stability;

5. Excellent quality assurance: Can pass UL-94 and RoHS disable poison test

The specific advantages of PMMA diffuser plate applied to the flat-panel lamp

1. Low processing costs. PMMA diffuser plate processing is easy, can be physical-mechanical cutting, and can be laser-cut or blow molding, blister and other hot forming methods, so in the early production of flat-panel lamps, PMMA plate is widely used;

2. Silk screen effect is excellent, with excellent ink absorption and adhesion. Flat-panel lamps are generally more monotonous, and now many vendors like to print their logos and electrical parameters on the flat-panel lamps, as well as a variety of decorative pictures. So if the customer needs a large area of silkscreen, the first choice of course is acrylic;

3. What we have to say is that the transmittance of the PMMA diffusion plate can reach about 90%. , but it is also troublesome to consider its ultra-high transmittance alone. It is well known that the flat-panel lamp is a reproduction of the backlight, the plane debris is also required, because of the strong light, it is very easy to cause bright spots and light guide plate mesh, defects visible and so on. Balance the transmittance and fog value is also very important.

4, The impact resistance is worse than PC but much higher than PS material.

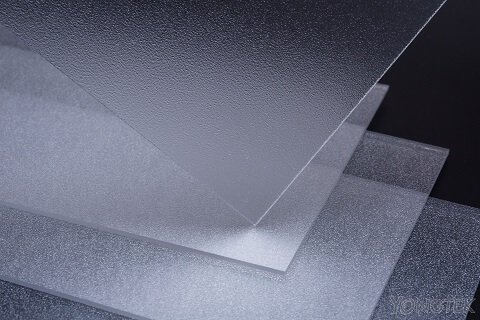

PS diffuser plate-polystyrene

1.Comparatively, the price is low,

2. Weather resistance is worse than PMMA, use in outdoor moisture, ultraviolet environment easy brittle, yellow degeneration is more obvious;

3. The weight is about 1.05g, lighter than PMMA (1.2), heavier than PP (0.96) ;

4. Suitable for machining, thermoforming. Considering the ease of integration, laser cutting processing is not suggested.

5. Surface scrub treatment, wear-resistant, scratch-resistant stability, the recommended use of the ambient temperature of 60-80 degrees.

6. The dimensional stability is good, the shrinkage rate of die making is within the 0.45% range.

7. With good surface antistatic properties, to prevent dust adsorption

8. Transmittance: 60%-85% (Adjustable range)

Above characteristics, visible PS diffuser plate has very good chemical stability, thermal stability, optical transmittance, strong refraction, electrical insulation, and very small moisture absorption, can be used in a humid environment, High radiation resistance. It can resist water and dilute inorganic acids.

At the same time, brittle, low impact strength, poor weatherability, long-term exposure to the outdoors prone to yellowing of the phenomenon. However, its heat resistance is so poor, the deformation temperature is 70-90°, can only be used in a 70° environment, its low-temperature performance is not good, embrittlement temperature is 30°.

PS has many drawbacks, but for flat-panel lamps, it is suitable, because flat-panel lamps are generally used indoors. It is used of temperature at-20-60°, which will not be long-term exposure to sunlight. It also has very good chemical stability and micro-hygroscopicity.

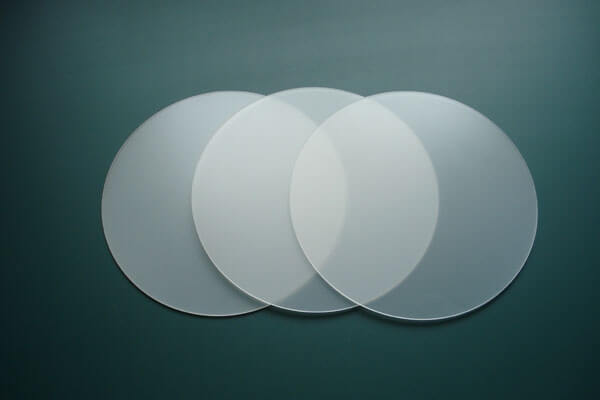

PC diffusion Board-Polycarbonate

1. High strength and elastic coefficient, strong impact strength, a wide range of use temperature,

1. High strength and elastic coefficient, strong impact strength, a wide range of use temperature,

2. High transparency and free staining,

3. H.D.T (Thermal deformation temperature, refers to the plastic under a certain pressure, the beginning of the deformation of the temperature)

4. Good fatigue resistance,

5. Weather resistance is good (weather resistance refers to the plastic products due to exposure to sunlight, temperature changes, rain, and other external conditions, and the appearance of fading, discoloration, cracking, powdering, and strength decline, such as a series of the aging phenomenon. Ultraviolet irradiation is the key factor to promote the aging of plastics.

6. Tasteless odorless harmless to the human body in line with health and safety,

7. Low forming shrinkage rate, good dimensional stability. Overall, PC stability is the best, fire-rated high, safety certification is better than, but in the production and sales, the price of the PC is more expensive, and in the installation of electrostatic too large, easy to absorb dust, also labor costs expensive.

PC’s light transmittance is relatively low, only about 86%!

PP Diffuser plate

This material is cheaper than PS. PP is added to the other materials made of synthetic, simple test comparison, summarized as follows:

1.Its toughness is excellent, similar to the PC;

2.Light transmittance and PC equivalent can reach about 85%;

3.Small electrostatic small, less dust absorption

4.Surface without film, production operation is simple.

Disadvantages:

First, the weather resistance is very poor, extremely easy to turn yellow,

The second is the material is extremely soft. In the production of 6060 of the flat lamp, because of its softer, after installed, it is naturally hanging up. The distance between the central to the guide plate can reach 2-3mm, it can very good control the droop of the shortcomings, this diffusion board will replace PS material.