LED lighting as a new type of green lighting, energy saving, environmental protection, long life, They are very popular all over the world. But the LED light failure is a big problem, a matter of LED lamps we have to face. Continuous light failure seriously effect the use of LED lamps. LEDAPlus Engineering Center summarizes several factors affecting today’s LED light failure.

For now, the white LED light failure on the market which may be one of the most important issue to the civil lighting march. What causes the LED light decline? In general, there are two major factors.

First, LED product itself quality problems:

1, the quality of LED chips are not good, brightness decay rapidly.

2, defects of the production process, LED chips can’t cool quickly from the PIN. Then the temperature of LED chips become too high and will increase the light failure.

Second, use properly.

1, LED need constant current driver, but some don’t use, and it will lead to light failure.

2, The driving current is greater than the rated driving condition.

In fact, there are still other reasons, but the most important reason is the hot radiation. Many manufacturers do not pay attention to the problem of heat dissipation. Other factors, heat resistance of LED chips, the impact of silver plastic, and the cooling effect of PCB, and so on. A good whole cooling structure is one of the outstanding advantages of LEDAPlus’s products in LED industry. The following is the patented LED integrated down light which was produced by LEDAPlus. With the whole design of aerospace aluminum, super good thermal performance.

Below there are three factors of LED light failure

First, how to choose a good LED white light

This is important, the quality of LED white light is a very important factor. For example, we use Epistar 14mil LED white chips for a test. If use ordinary epoxy primer and white light glue to pack. Light the LED chips in a environment of 30 Celsius degree, after 1000 hours, the percentage of failure decrease to 70%; If use D glass aiti light failure glue, and in the same environment, same time, the percentage of light failure decrease to 45%. If use C glass aiti light failure, it will be 12%. So B,6%. A,3%.

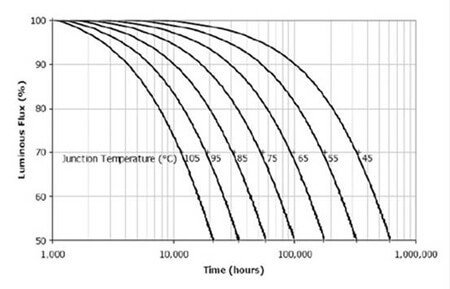

Second, work environment temperature of LED chips

We did a experiment. If a single LED chips is lighting in 30 Celsius degree, then the temperature of LED chip fixture is no more than 45 Celsius degree.

In this case, it is a perfect temperature for LED chips. If 100pcs LED chips are lighting at the same time, and the span between no more than 11.4mm. Then temperature of those chips on the side is no more than 30 Celsius degree. But for other LED chips, the temperature will reach to 65 Celsius degree.Basically speaking, those chips on the side will lose light quicker than those in the center.

Third, LED chips’ electrical design parameters

Based on the experimental results, LED white light at lower drive current, heat emission is smaller, of course, the smaller the brightness. According to the survey, LED solar lighting circuits, LED drive current is only 5-10mA; For the big power LED light with more than 500 pcs LED chips, the drive current is only 10-15mA.and the general popularity of LED lighting applications drive current, just 15-18mA. Few people design the current more than the 20mA.

The results also show that the drive current of 14mA, and added a lid unventilated inside air temperature reaches 71 Celsius degree below ambient, low decay products, lighting for 1000hours, light failure is zero, 2000 hours only 3%, which shows such a low failure LED white light used in such an environment has reached its maximum, then big is it the kind of damage.

The aging board can’t lose heat while aging testing. So the heat generate from LED light can’t release effectively. The test proved this. The temperature inside aging board reached to 101 Celsius degree, but the lip of aging board only 53 celsius degree. But when we design a LED light, we have to consider how to release heat effectively. In a word, if the light can release heat effectively, it is fine when we increase the current. Otherwise, we would like to use small current and generate fewer heat, decrease the light failure.