With the rapid expanding of the solid-state lighting (SSL) technology, the COB (chip-on-board) more and more became in focus. Cause of the better traits, such as low heat resistance, low heat resistance, low glare index, uniform luminance and so on, the COB light sources are used widely in outdoor and indoor lighting projects as down light, Bulb Light, Tube light, street lamp and LED bay light.

The article aims to explaining the advantage of the COB packaging compared with the traditional LED packaging on five aspects of Manufacturing effectiveness, Low heat resistance, Quality of light, Application and Cost advantage, to show the COB packaging become to a leading role in the development of LED lighting.

1,Manufacturing effectiveness

Difference of LED Light Chips, COB and SMD

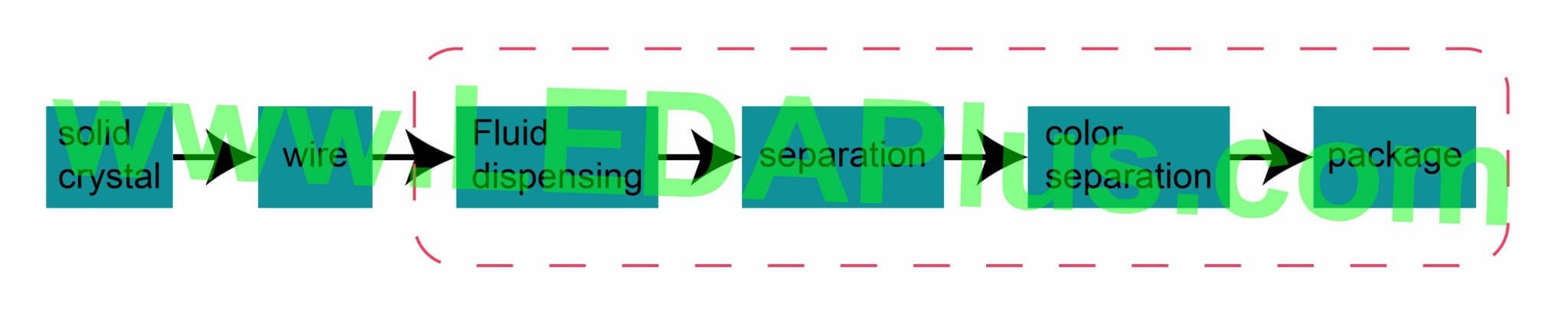

The production process of the COB is same as the traditional SMD, such as the solid crystal, wire. But for the productivity of fluid dispensing, color separation and package, the COB is much higher than the SMD. The cost of the labor and the material of the SMD is about 15% in the total, in the other hand, it is just 10% for the COB, that means if you use COB in your LED lights, 5% of the cost can be saved.

2, Low heat resistance

Difference of LED Light Chips, COB and SMD

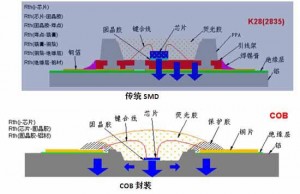

The way to dissipate heat of the SMD is Chips – solid glue – solder – solder paste – copper foil – insulating layer – aluminum plate, the one for the COB is shorter, just Chips – solid glue – aluminum plate. That is why the heat resistance of the COB system is lower than the SMD, and that leads to a more longer useful life for the LED lighting.

3, Quality of light

Difference of LED Light Chips, COB and SMD

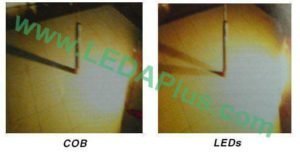

The packaging of COB is integrated style, it is area light source, the advantage is big visual angle and easy to change it, and also to to cut the loss of the refraction of light, but the SMD is packaged by several discrete units to stick in PCB plate, it cause dazzle and ghosting.

4, Application(e.g. COB tube)

Difference of LED Light Chips, COB and SMD

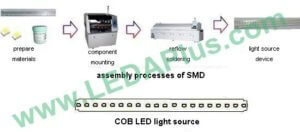

As the picture shows, to make a COB light source, it do not need component mounting and reflow soldering, that means no need the machines in the factory, so the cost cut sharply and the production time will be shorter.

Take a 1.2m, 2000LM tube as sample, it about need 288pcs 3528 SMD, and the cost of mounting is about 0.01RMB/pc, so the total mounting cost is 288pcs*0.01RMB/pc=RMB2.88 for the 1.2m tube light, but using the COB will saving it!

5, Cost

You can find the above 1 and 4 point, both of them show how the COB save money!